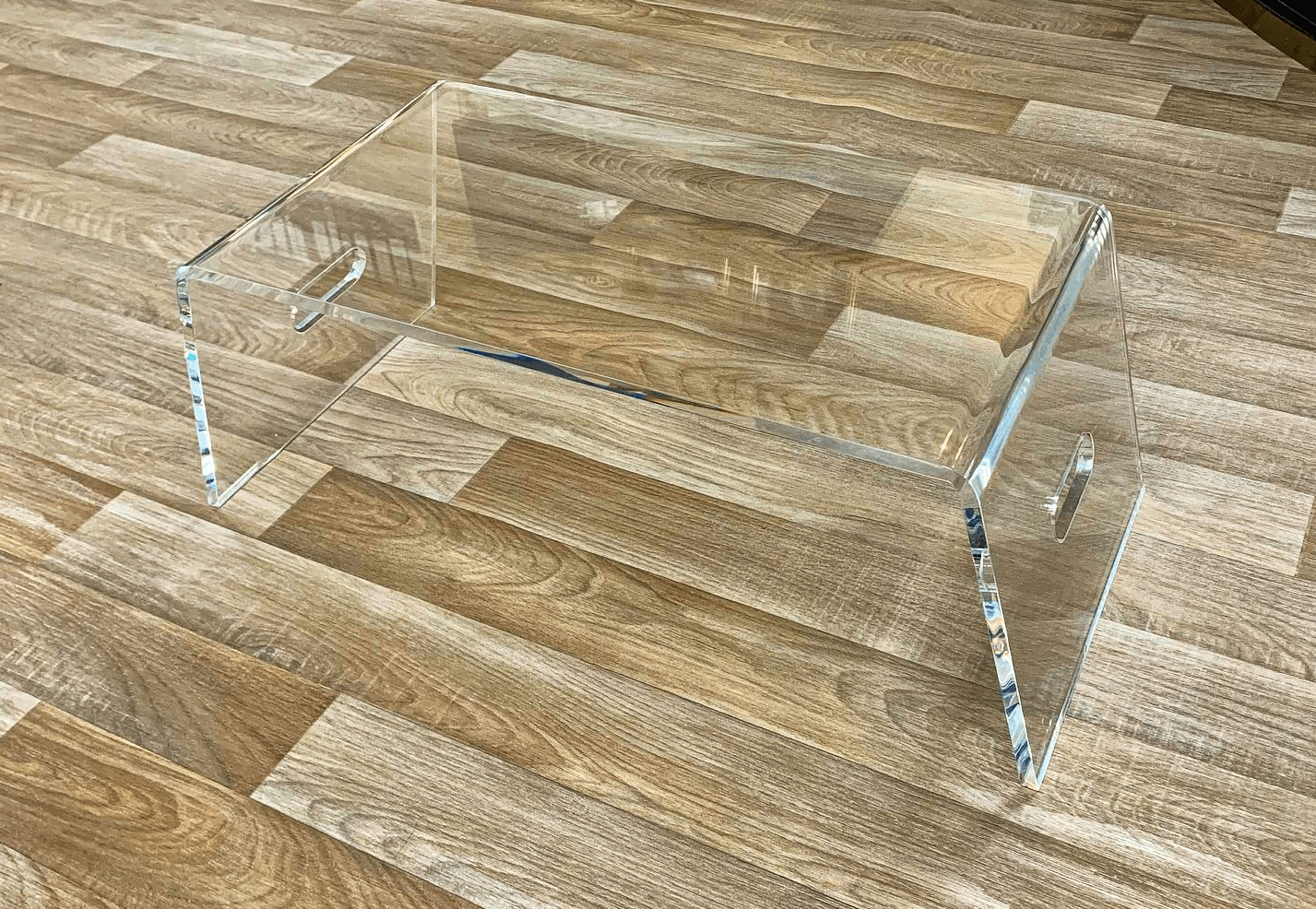

Acrylic is mainly a human-made material like polycarbonate, also called Plexiglass. Acrylic gives a clyster clear glass effect which makes it look more beautiful. Acrylic is all over the place at the current times, it gives a beautiful vision too. This transparent and versatile material seems fabulous in a variety of settings and thus complements a broad range of design patterns

Acrylic polishing is one of the best ways to care for acrylic products. Acrylic products are usually polished because it provides a perfect finishing. It is so because most often acrylic products carry dents well. The unwanted areas on acrylic products need proper polishing, as it provides the correct shape to the final product.

An acrylic product that finishes professionally is more profitable as compared to an unfinished one. An acrylic product that is polished is having a more professional elegance than other ones. Thus, professionalism and sales polishing are a must for acrylic products.

Points to keep in mind before polishing acrylic products:

Different approaches used for acrylic Polishing, the best way to take care of acrylic can be are given as follows:

1. Polishing of the edge

You can craft a higher level of product finishing on its edge. If you have an edge that effectively passes through the grinders, then polishing can be done with the edges and there is no need of using sand.

The polishing compound is another factor that decides the final result of polishing. If someone likes to make a shinier look, then they can use speedy compounds for cutting, to remove any kind of unwanted marks of sand from the product.

2. Polishing of the Surface

If your product carries any machinery mark with no very internal effect, then you have the option to polish the surface of the product without using sand. You can use muslin also which has gone through the bleaching process because it becomes soft after that.

Whenever polishing any part of the product, you should keep that area cool while in motion all the time. Don’t make use of high pressure; it will lead to damage to your product because of the high temperature. These steps should be followed while making Acrylic Tables, acrylic display stand, and other stuff.

3. Rub-down the Edges

Sanding or rubbing of the edges can be done in dry or wet any two ways. You can use your hands and lots of water while sanding the edge. Use sand bock for creating perfectly even edges.

4. Rub-down the Surface

Rubbing surfaces shouldn’t be complete if you find any unwanted bumps or dents which are not go away even after polishing. You should use plenty of water for creating a perfect finishing. A sheet usually gets highly heated if you are not using water.

If you are looking for companies that provide their services for acrylic products in Dubai, you can visit our company’s website. Feel free to contact us at Professional Acrylic LLC.