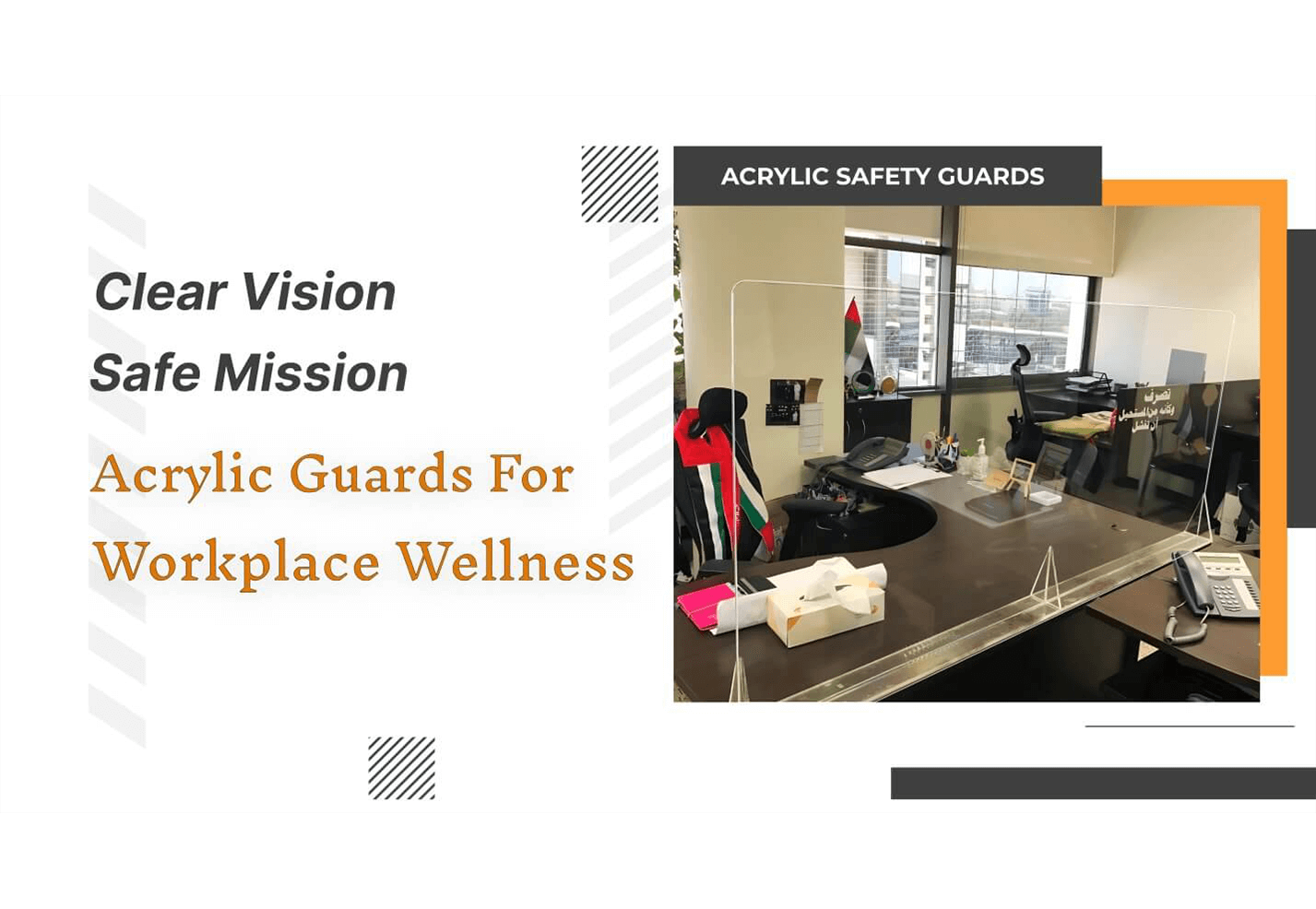

In many workplaces, safety is a priority and employers must take steps to ensure that their employees are safe while they’re on the job. One way to do this is by implementing acrylic safety guards in key areas of your workplace. In this article, we will discuss why acrylic safety guards are the best choice for keeping your workplace safe and how they can be implemented effectively and efficiently.

Benefits of Acrylic Safety Guards

1. Acrylic safety guards can help to prevent injuries.

2. Acrylic safety guards can help to keep employees safe from harmful chemicals and other substances.

3. Acrylic safety guards can help to create a barrier between employees and potential hazards.

Types of Acrylic Safety Guards

How to Install an Acrylic Safety Guard

Wrapping Up

Acrylic safety guards are an effective and affordable solution for ensuring safety in the workplace. By providing a physical barrier between employees, they can help reduce the risk of injury or even death due to accidental contact with hazardous equipment. Additionally, they are easy to install and maintain, making them ideal for most workplaces.

With all these advantages, it is easy to see why acrylic safety guards have become such a popular choice among companies that value the well-being of their employees.